Product weight stability is the desired result of each injection molding manufacturer. At the same time, product weight is also an important control parameter in quality management.

The weight stability of injection molded parts is not a sufficient condition for stable production, but a necessary condition. If the weight deviation is large, the production stability must be low. Such production is unstable production, or the production is not “precise”.

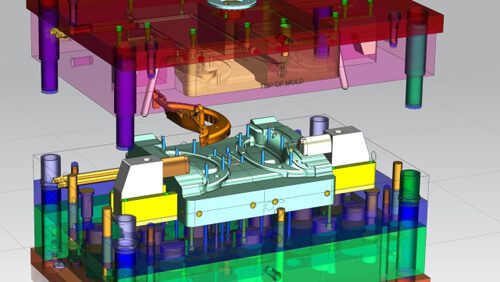

High weight stability is an important index of precision production. Although the main body of precision injection molding production is injection molding machine, precision production is the stable effect of all aspects of production, including materials, molds, injection molding machines and peripheral equipment. If other indexes are well controlled, the machine can play a stable role. If other parameters are unstable, the precision production will certainly not be achieved.

For products of the same size, there are many factors affecting the final product weight. To sum up, there are the following:

1) Design. size of reinforcement; Wall thickness, etc.

2) Process. the increase of holding time and pressure will increase the weight of the product; The relationship between product weight and mold temperature is U-shaped.

3) Mold type. with the same size, the weight of air assisted is lighter than that of non air assisted.

4) Raw material. the same is PP, and the density of different brands has slight differences.

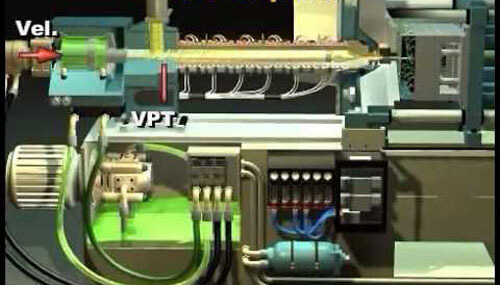

5) Control of injection molding machine

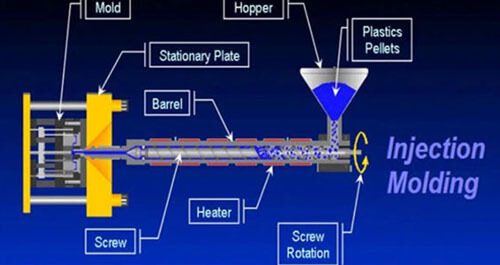

One of the factors to talk about today is the injection molding machine The five control parameters of the injection molding machine – pressure, speed, position, time and temperature have an impact on the weight change. Without changing the parameters in continuous production, the temperature that has the greatest impact on the weight stability of the product.

1) Temperature and purity of hydraulic oil.

The temperature of hydraulic oil directly affects the oil viscosity, control pressure and speed, especially when the equipment is not fully closed-loop control. When the purity is low, the flow valves of each proportional valve may be blocked. Therefore, the hydraulic oil will affect the weight stability. The main factor affecting the oil temperature is the efficiency of the oil temperature cooler, so pay attention to the hardness and cleanliness of the external circulating water. If the hardness is high and the cleanliness is poor, the efficiency of the cooler must be poor, and the increase of oil temperature is inevitable.

2) Mold temperature, especially the temperature of mold cavity surface.

This depends on two points: the stability of the forming cycle and the stability of the cooling water. The cooling water flow is large, the cooling effect is good, the hardness is low, and the water path will not be blocked.

3) Stability of barrel temperature and flow.

The temperature stability is mainly due to the reasonable back pressure without excessive shear heating, but generally, the barrel with back pressure lower than 30kg will not automatically heat up. The stability of flow is mainly sealing. The wear of three small parts on the screw head will be stable if there is no wear.

4) Others, such as the drying effect of plastic materials.

The cleanliness of plastic materials. If there are foreign matters, the flow of molten materials fluctuates and the production will not be stable.

If the above are well controlled, the rest depends on the precision of the machine. Weight repeatability is a very important index in precision injection molding. It is generally believed that “the weight repeatability of ordinary injection molding machine is 1%, that of precision injection molding machine is less than 0.5%, and that of ultra precision injection molding machine is less than 0.3%”.