Service - Surface Treatment Services

About Surface Treatment Services

At Batnon, we provide comprehensive surface treatment services designed to enhance the performance, aesthetics, and durability of your products. By combining advanced techniques, skilled craftsmanship, and cutting-edge technology, we ensure that every component achieves the desired surface quality and functionality. This page highlights our surface treatment capabilities and explains why Batnon excels in this field.

What is Surface Treatment?

Surface treatment involves modifying the exterior layer of a product to improve its appearance, resistance to wear, corrosion protection, or functionality. This essential step can significantly enhance the lifespan and performance of parts, especially in demanding environments.

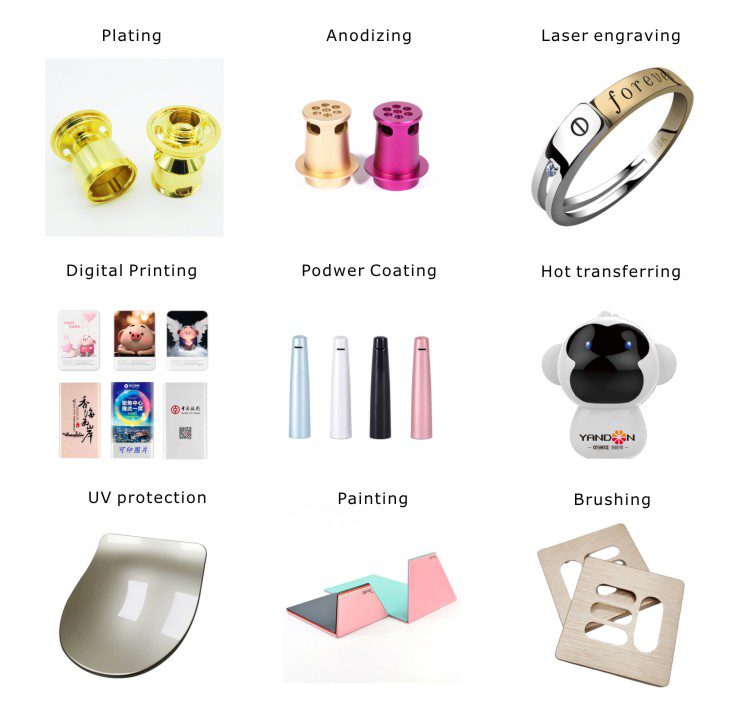

Key Surface Treatment Services We Offer

1. As-Machined Finishes

Description: Smooth, standard finish directly from the CNC process without additional treatment.

Applications: Ideal for parts requiring no aesthetic enhancements but retaining precise dimensions and functionality.

2. Polished Finishes

Description: A reflective, glossy surface achieved through meticulous polishing techniques.

Applications: Suitable for decorative components or parts requiring smooth contact surfaces.

3. Anodizing

Description: An electrochemical process that enhances corrosion resistance, durability, and appearance. Available in multiple colors.

Applications: Widely used in automotive, electronics, and consumer products.

4. Powder Coating

Description: A durable, wear-resistant finish applied as a dry powder and cured under heat.

Applications: Ideal for outdoor products, industrial machinery, and components requiring long-lasting finishes.

5. Sandblasting

Description: A process that uses abrasive materials to create a uniform matte surface.

Applications: Commonly used for aesthetic enhancement and surface preparation before additional treatments.

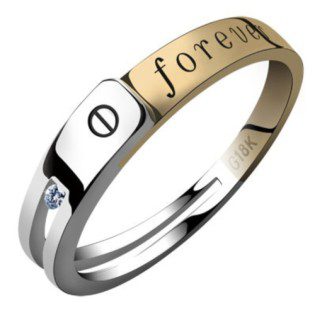

6. Plating

Description: The application of metal coatings (nickel, zinc, or chrome) for functional or decorative purposes.

Applications: Enhances corrosion resistance and provides a premium look, often used in consumer goods and industrial equipment.

7. Galvanizing

Description: Zinc coating applied to steel or iron parts for enhanced corrosion resistance and durability.

Applications: Ideal for outdoor and industrial applications.

8. Electrophoresis

Description: An electrically-applied coating that provides a smooth, durable surface finish.

Applications: Suitable for decorative or functional parts requiring high corrosion resistance.

9. Tumbling

Description: A finishing process that smooths and polishes parts by rotating them with abrasive media.

Applications: Removes sharp edges, achieves uniform matte or polished finishes, and is ideal for small or intricate components.

Why Choose Batnon for Surface Treatment?

1. Advanced Technology

We use state-of-the-art machinery and techniques to ensure precision and consistency in every surface treatment process.

2. Customization Options

Our services are tailored to meet the specific requirements of each project, offering a wide range of finishes and coatings.

3. Skilled Workforce

Our experienced technicians and engineers bring expertise and attention to detail, ensuring the highest quality standards.

4. Integrated Process

As part of our “Integrated Process” approach, we seamlessly incorporate surface treatments into the overall production workflow, reducing lead times and costs.

5. Environmentally Responsible Practices

We adhere to eco-friendly practices, minimizing waste and using sustainable materials where possible.

Applications of Our Surface Treatments

Our surface treatments are designed to meet the diverse needs of industries worldwide. Applications include:

Automobile: Enhancing durability and aesthetics of vehicle components.

Automation: Providing wear-resistant and precise finishes for automated machinery.

Medical: Ensuring hygienic, corrosion-resistant surfaces for medical instruments and devices.

Energy: Protecting equipment from environmental factors in energy production.

Robotics: Enhancing the performance and longevity of robotic components.

Electrical: Offering conductive and protective finishes for electrical systems.

Aerospace: Providing lightweight, durable coatings for critical aerospace parts.

Consumers: Creating visually appealing and functional finishes for household items.

Food and Beverage: Ensuring safe and durable finishes for food processing equipment.

Electronics: Providing corrosion resistance and conductive finishes for electronic parts.

Printing: Extending the lifespan of printing equipment through protective coatings.

Machinery and Equipment: Increasing the durability and performance of industrial machinery.

Aircraft: Delivering high-performance finishes for aviation components.

Examples of Success

Case Study 1: Corrosion-Resistant Coatings for Outdoor Equipment

We applied galvanizing and powder coating to outdoor steel components, increasing their lifespan by 50%.

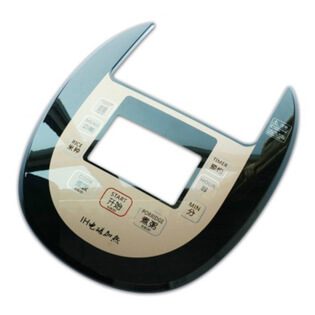

Case Study 2: Premium Finish for Consumer Electronics

Our polishing and anodizing processes gave a high-end aesthetic to a series of electronics, boosting market appeal.

How We Innovate in Surface Treatment

Research and Development: Continuously exploring new techniques and materials.

Quality Control: Implementing rigorous inspections to maintain consistency and precision.

Client Collaboration: Working closely with clients to align treatments with their goals and requirements.

anodizing

electric plating

painting

bead blasting

hot transfer

polishing

brushing

IMD decoration

powder coating

digital printing

laser engraving

UV coating

Enhance the performance and appearance of your products with our surface treatment services. Contact us today to learn more about our offerings and how we can add value to your projects.