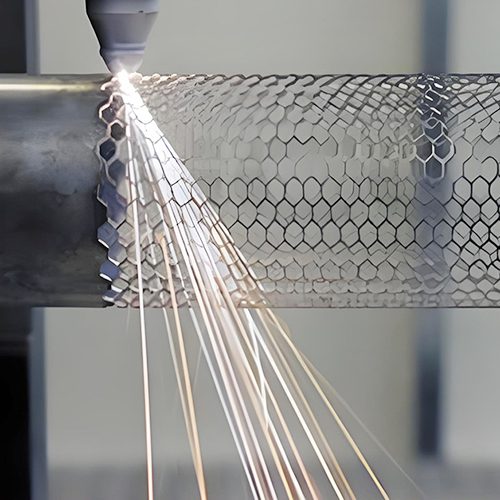

Our Laser Cutting

At Batnon, we offer industry-leading laser cutting services to create precise, intricate, and high-quality parts for various applications. Whether it’s metal laser cutting, acrylic, or other materials, our advanced technology ensures clean edges, minimal waste, and superior results for every project.

Overview on Laser Cutting at Batnon

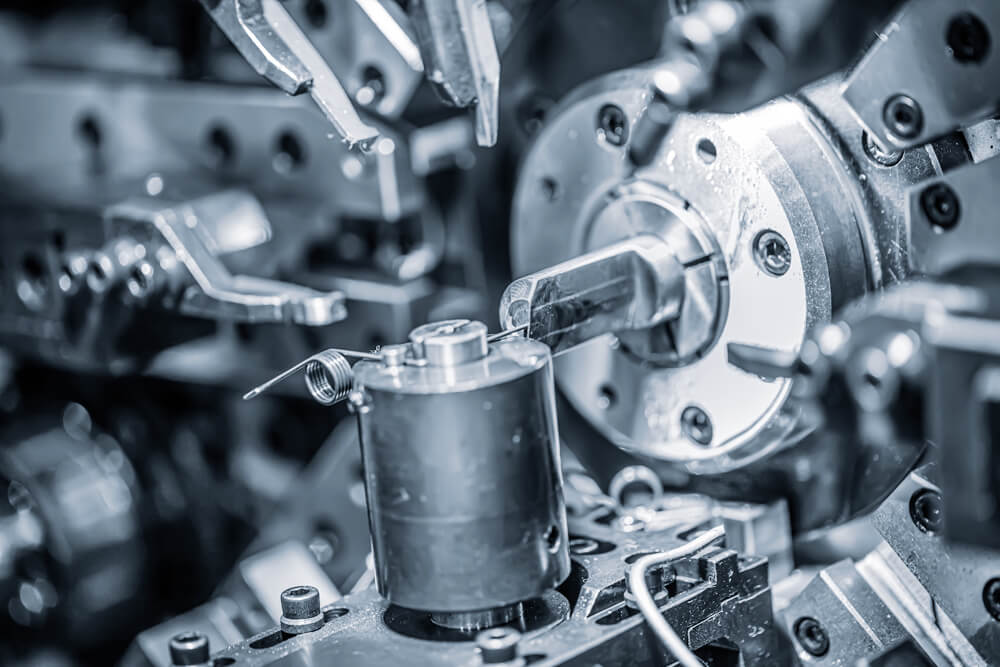

Laser cutting is a versatile, high-precision process that uses concentrated laser beams to cut through materials with exceptional accuracy. Our cnc laser cutting capabilities are ideal for intricate designs, rapid prototyping, and mass production, offering unmatched flexibility for a wide range of industries.

Our Laser Cutting Capabilities

Key Features of Our Laser Cutting Services

- Precision Cutting: Achieving tolerances as tight as ±0.05mm for intricate designs.

- Material Thickness: Capable of cutting materials up to 25mm thick, depending on the material.

- Versatile Applications: From cutting sheet metal to tube laser cutting, we handle both flat and 3D components.

- Custom Solutions: Tailored cutting patterns for unique designs and specific industry requirements.

Advantages of Choosing Batnon for Laser Cutting

- Unmatched Precision: Clean, burr-free cuts for even the most intricate designs.

- Efficiency: High-speed cutting reduces lead times and increases productivity.

- Material Versatility: Compatible with metals, acrylic, wood, and specialty materials.

- Cost-Effective: Minimizes waste and eliminates the need for secondary finishing.

- Scalable Production: Perfect for both prototypes and large production runs.

Applications of Laser Cutting

Our laser cutting services excel in creating components such as:

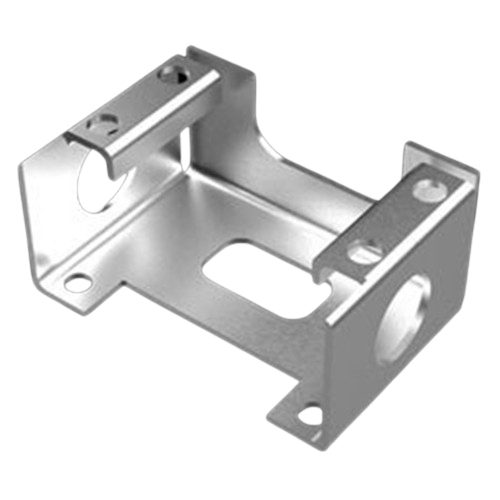

- Automotive Parts: Precision brackets, panels, and decorative trims.

- Architectural Elements: Custom screens, signage, and intricate designs.

- Electronics: Enclosures, heat sinks, and custom casings.

- Industrial Equipment: Durable machine parts and fixtures.

- Consumer Products: Customized designs for furniture, appliances, and hardware.

Industries Served

Batnon’s laser cutting services support a wide range of industries:

- Automobile: Lightweight panels and decorative trims.

- Automation: Custom components for automation systems.

- Medical: Precision-cut surgical instruments and device components.

- Energy: Durable parts for renewable and traditional energy systems.

- Robotics: Custom-cut parts for robotic assemblies.

- Electrical: Enclosures and precise cut-outs for electrical components.

- Aerospace: Lightweight, intricate components for high-performance applications.

- Consumers: Aesthetic and functional parts for everyday products.

- Food and Beverage: Corrosion-resistant machine parts for processing equipment.

- Electronics: Custom enclosures and parts for compact devices.

- Printing: Precision-cut components for printing equipment.

- Machinery and Equipment: Durable and reliable structural parts.

- Aircraft: High-strength, lightweight components for aviation systems.

Materials

Materials We Work With

- Metals: Stainless steel, aluminum, brass, copper, and carbon steel.

- Plastics: Acrylic, polycarbonate, and engineering plastics.

- Other Materials: Wood, composites, and specialty materials for unique projects.

Material Recommendations

- Stainless Steel: Ideal for durability and corrosion resistance, commonly used in medical and food-grade applications.

- Aluminum: Lightweight and versatile, suitable for aerospace and automotive components.

- Acrylic: Perfect for acrylic laser cutting, offering a polished edge finish for signage and displays.

- Wood: For custom designs in furniture, decor, and woodworking applications.

Tolerances

Our laser cutting process ensures exceptional precision:

- Standard Tolerances: ±0.1mm for general applications.

- High-Precision Tolerances: ±0.05mm for intricate and critical components.

Tolerances Matter

Why It Matters: Tight tolerances ensure that every part fits perfectly, reducing the need for secondary processing.

Surface Finishes

Enhance the functionality and appearance of your laser-cut parts with professional surface treatments:

- Polishing: For a clean, shiny finish on metal surfaces.

- Anodizing: Protective and aesthetic oxide coatings for aluminum parts.

- Powder Coating: Durable and uniform coatings in a variety of colors.

- Plating: Nickel or zinc plating for added corrosion resistance.

Navigating the complexities of laser cutting can be challenging. Our team of experts is here to guide you through the process, from design to material selection and production.

Quality Control

Inspection Tools:

- 3D Coordinate Measuring Machines (CMM).

- Laser scanners for dimensional verification.

Processes:

- 100% inspection for critical dimensions.

- Comprehensive testing for strength, surface finish, and material integrity.

Certifications:

- ISO-compliant processes for guaranteed reliability.

Case Study

Project Requirement:

A client needed intricate laser cut steel sheet designs for custom signage with precise dimensions and a polished finish.

Our Solution:

Material Selection:

We chose 6061 Aluminum for its excellent strength-to-weight ratio, corrosion resistance, and machinability, meeting both functional and aesthetic needs.Process:

- Used 5-axis CNC milling to precisely machine the intricate geometries in a single setup, ensuring high accuracy and efficiency.

- Applied custom tooling to create smooth internal channels for wiring and cooling without additional assembly.

- Implemented rigorous quality checks at every stage, including dimensional verification using a Coordinate Measuring Machine (CMM).

Surface Finish:

Delivered a polished surface with a protective anodized coating to enhance durability and resist wear during prolonged use.

Results:

- Precision Achieved: Maintained a dimensional accuracy of ±0.005mm across all critical points, ensuring perfect alignment with other components during assembly.

- Lightweight and Durable: The frame weighed 15% less than traditional designs while maintaining superior strength.

- On-Time Delivery: Completed production within 12 days, ahead of the client’s 15-day deadline.

Client Feedback:

The client praised the part’s exceptional quality and early delivery, enabling them to successfully integrate it into their robotics system and launch on time.

Impact:

This project reinforced Batnon’s reputation as a trusted CNC milling partner for high-precision, time-sensitive projects, particularly in the robotics and automation industries.

Ready to elevate your project

with our precision CNC machining services?