CNC Machining Manufacture Types and Materials?

What are CNC Machining Manufacture Types? Ordinary lathe is the most commonly used machine for turning parts. Turning is the removal of metal from the workpiece. When the workpiece rotates, the tool cuts along the workpiece. Boring is a method of enlarging or further machining holes drilled or cast on metal workpieces. Boring on the […]

Polishing Methods And Technical Points Of High Gloss Mold

1. Mechanical Polishing Mechanical polishing is a polishing method to obtain a smooth surface by cutting and removing the convex part after polishing due to plastic deformation of the material surface. Generally, oilstone strips, wool wheels, sandpaper, etc. are mainly used for manual operation. For special parts such as the surface of the swivel, turntable […]

How To Control The Weight Of Injection Molding Products?

Product weight stability is the desired result of each injection molding manufacturer. At the same time, product weight is also an important control parameter in quality management. The weight stability of injection molded parts is not a sufficient condition for stable production, but a necessary condition. If the weight deviation is large, the production stability […]

Surface treatment process of aluminum alloy

The surface treatment methods of aluminum alloy include anodic oxidation, electroplating, infiltration, surface spraying, shot peening and vacuum spraying. 1. Anodizing Anodizing method is a method to form a layer of oxide film on the surface of workpiece or product by using the electrolysis principle of DC and AC / DC, so as to increase […]

Principles of material selection in product design

1) Safety first principle. The product is ultimately used by users, so the material selection should ensure its safety in the process of production and use and ensure protect human health and physical and property safety from injury or loss. Designers should first understand the needs of material selection through the analysis of the physiological […]

How Extrusion Profile Is Made?

Main content: Processing Procedure of Aluminum Extrusion Profile. The processing process of aluminum profile includes the following three steps: melting & refine, extrusion and coloring (the key of coloring includes oxidation, electrophoresis process, fluorocarbon painting, electrostatic powder spraying, wood grain transfer, etc.). This article is about these three steps. 1. Melting and Refining Melting is […]

Aluminum Part Die Casting Production Process

Aluminum part die casting is not only suitable for casting of various types and alloys, but also the casting size precision and surface quality produced are higher than other casting methods. Even the castings which are difficult to be cast by other casting methods are complex, high temperature resistant and difficult to process. They can be […]

Manufacturing Process of Die Casting Mold

Whole Processing Procedure: Drawing review – material preparation – processing – mold base processing – mold core processing – electrode processing – mold parts processing – Inspection – assembly – flying mold – trial mold – Production A: Mold base processing: 1 dozen number, 2 A / B plate processing, 3 panel processing, 4 thimble […]

What are the advantages of 3D printing?

3D printers don’t make things by cutting or molding, as traditional manufacturing machines do. Through the method of layer by layer stacking to form physical objects, the scope of digital concept is expanded from the physical point of view. 3D printer is the preferred processing equipment for shape design with precise internal concave or interlocking […]

3D printing process

In Batnon’s integrated processing, one tool and stage we can not miss is 3D printing. The following messages introduce how a full 3D printing process will go. 1. Modeling Generally speaking, 3D modeling is to build a model with 3D data from virtual 3D space through 3D production software. For example, if you want to […]

What is Plastic Injection Molding Process?

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. It is commonly used for producing plastic components, though it can also be used with metals, glasses, and elastomers. In all of contents on Batnon, injection molding solely refers to plastic injection manufacturing. Here’s an overview of the […]

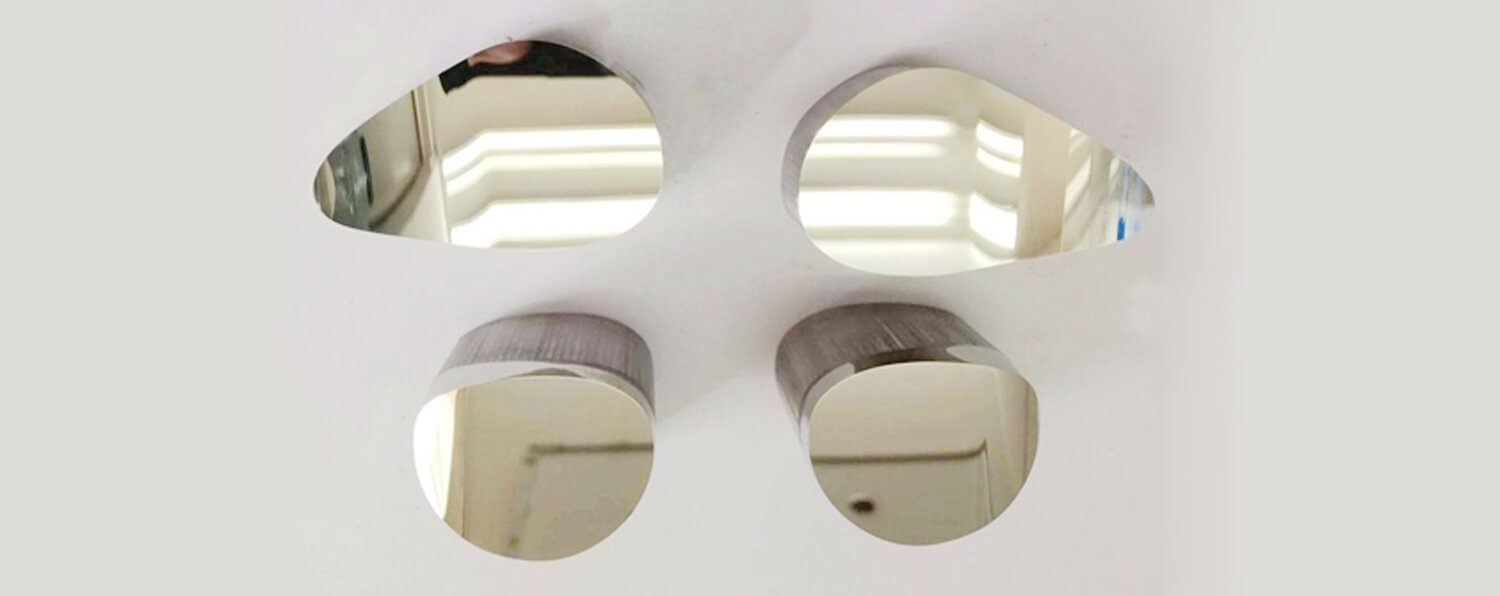

Polishing Process of Plastic Injection Mold

The Polishing Process of Plastic Injection Molds: A Key to Superior Quality In the realm of plastic injection molding, the final quality of your product often hinges on the meticulous attention given to the mold. For producing those parts with highly shiny surface effect, one of the most critical steps in ensuring that your plastic […]