Plastic Mould and Injection Services

Table of Contents

Toggle1. What Are Plastic Mold and Injection Services?

Plastic mold and injection services involve the creation of plastic parts / components through a specialized manufacturing process. This process involves designing and creating molds, which are then used to shape molten plastic into desired forms, geometries, and dimensions.

2. The Importance of Plastic Mold and Injection Services

Plastic mold and injection services have been a critical production method in the manufacturing of plastic parts and products across various industries. Products made with plastic mold and injection are so popular in today’s world that it has become a indispensible process. These services bring numerous benefits, enabling manufacturers to create high-quality, precise, and cost-effective plastic parts / components.

- Precision and Consistency

One of the primary advantages of plastic mold and injection services is the ability to produce parts with exceptional precision and consistency. The molds are crafted to exact specifications, ensuring each component meets stringent tolerances. This precision is crucial in industries such as automotive and medical devices, where even minor deviations can have significant consequences. - Efficiency and Speed

Production with Injection mold is a highly efficient way, allowing for the rapid production of large volumes of parts. Once the mold is fabricated, the injection process can be repeated quickly, producing thousands of identical components or even more in a short period. This efficiency brings faster turnout and the ability to meet high demand without compromising on quality. - Cost-Effectiveness

The initial investment in mold creation can be offset by the cost-effectiveness of the injection molding process. The ability to produce large quantities of parts quickly reduces labor costs and minimizes material waste, therefore, diluting the mold investment across each piece produced. This makes plastic mold and injection services an economical choice for both small and large-scale production runs. - Versatility

Plastic mold and injection services offer unparalleled versatility in terms of design and material selection. Molds can be designed to produce complex shapes and intricate geometries that would be difficult or impossible to achieve with other manufacturing methods. Additionally, a wide range of plastic materials can be used, each offering different properties such as flexibility, strength, and resistance to chemicals or heat, respectively catering for different use demand. - High-Quality Finishes

Parts made with Injection molding can come with smooth surfaces and high-quality finishes, which reduces the need for additional processing or finishing. This is particularly important for consumer goods and medical devices, where the appearance and texture of the product are critical, while persuing a cost effective solution at the same time. - Customization and Flexibility

The plastic mold can be customized for specified product geometric design, manufacturers then are able to produce parts tailored to specific applications. Whether it’s creating unique product designs, incorporating branding elements, or meeting specific functional requirements, plastic mold and injection services offer the flexibility to meet diverse needs. - Scalability

Injection molding is highly scalable, making it suitable for both low and high-volume production. Manufacturers can start with small production runs to test the market and scale up to mass production as demand increases. This scalability ensures that businesses can grow without needing to invest in new manufacturing processes.

Conclusions:

Plastic mold and injection services are essential for manufacturing high-quality plastic parts and products. Their precision, efficiency, cost-effectiveness, and versatility make them a cornerstone of modern manufacturing across a wide range of industries. By leveraging these services, manufacturers are able to achieve superior product quality, meet diverse market demands, and drive innovation in their respective fields.

3. Application of Plastic Mold and Injection

The importance of plastic mold and injection services extends across numerous industries, including:

- Automotive: Essential for producing components such as dashboards, bumpers, and engine parts.

- Electronics: Used in the manufacture of casings, connectors, and various small parts.

- Medical Devices: Critical for producing sterile, high-precision components like syringes, implants, and diagnostic tools.

- Consumer Goods: Vital for creating everyday items such as household products, toys, and packaging materials.

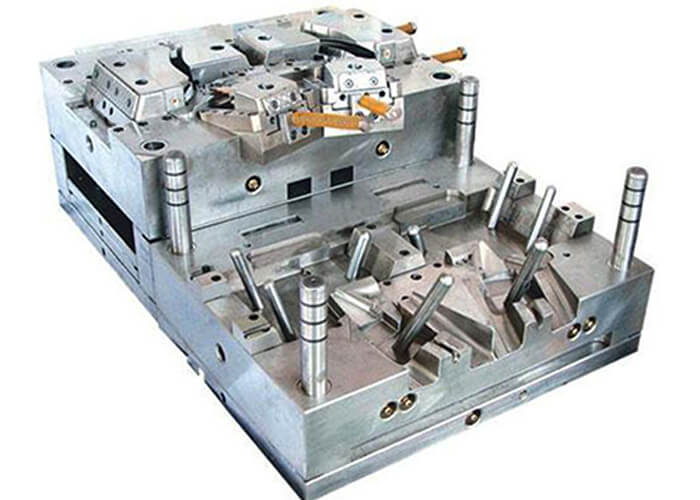

4. Our Capabilities In Plastic Mold Design And Fabrication

At Batnon, we’re proud of being able to offer comprehensive plastic mold design and fabrication services that makes standing out in the industry. Our advanced capabilities ensure that we can meet the most demanding requirements, delivering precisely fabricated molds and high-quality plastic parts for a wide range of applications. Here we detail it as following.

1) Advanced Mold Design

- Customized Services

Our team of experienced engineers and designers works closely with clients to create custom mold designs tailored to their specific needs. We utilize the latest CAD (Computer-Aided Design) software to develop detailed and accurate designs, ensuring that every mold meets exact specifications and desired requirements. - Prototyping and Testing

We understand the importance of getting the design right before full-scale production, so we conduct validation through simulation on computer along with prototype. Our prototyping services allow us to validate design before creating actual molds, make necessary adjustments to ensure optimal performance and functionality. This process helps to identify and resolve potential issues early, saving time and resources in the long run. - Complex Geometries and Intricate Details

Our expertise in mold design extends to creating molds for parts / components complex forms and intricate details. Whether it’s a simple component or a highly detailed part, our design capabilities ensure precision and consistency in every mold we produce.

2) State-of-the-Art Mold Fabrication

- High-Quality Materials

We use only the highest quality materials in our mold fabrication process, ensuring durability and longevity. Our selection of materials is based on the specific requirements of each project, including considerations for heat resistance, wear resistance, and the type of plastic to be molded. - Advanced Manufacturing Techniques

Our fabrication facilities are equipped with advanced machinery and technology, including CNC machines, EDM (Electrical Discharge Machining), wire-electrode cutting, polishing machine, inspection tools, and other state-of-the-art equipment. These tools allow us to create molds with tight tolerances and high precision, ensuring the final product meets the highest standards of quality. - Rigorous Quality Control

Quality is at the core of everything we do. Our rigorous quality control processes include detailed inspections at every stage of the mold fabrication process, such inspection are conducted at any time. We employ advanced measurement tools and techniques to verify dimensions complying with requirements and ensure that every mold we produce meets our stringent quality criteria.

3) Capabilities in Mold Maintenance and Repair

- Regular Maintenance

Molds need maintenance in time. To ensure the longevity and performance of our molds, we offer regular maintenance services. Our team employs routine inspections and maintenance to prevent wear and tear, ensuring that the molds remain in optimal condition throughout their lifespan for production. - Efficient Repairs

In the event of damage or wear, our repair services take actions for quickly restoring molds to their original condition. Our skilled technicians are adept at diagnosing issue root and implementing effective repair solutions, minimizing downtime and ensuring continuous production.

4) Expertise Across Industries

Our capabilities in plastic mold design and fabrication extend across various industries, including:

- Automotive: Molds for interior and exterior components, engine parts, and more.

- Electronics: Precision molds for casings, connectors, and small electronic parts.

- Medical Devices: High-precision molds for sterile and intricate medical components.

- Consumer Goods: Molds for a wide range of household items, toys, and packaging solutions.

- Machinery and equipement

- Automation

- Electric

5) Commitment to Innovation

At Batnon, we are committed to continuous innovation and improvement. We invest in the latest technologies and training for our team to stay at the forefront of the industry. Our goal is to provide our clients with the most advanced mold design and fabrication services available, helping them bring their innovative products to market with confidence.

Partner with Us

When you choose Batnon for your plastic mold design and fabrication project, you are partnering with a team dedicated to excellence and customer satisfaction. Contact us today to learn more about our capabilities and how we can help you achieve your manufacturing goals.

5. Precedures from Mold Design to Final Production

The journey from mold design to final production in the injection molding process involves several critical steps. Each step ensures that the final product meets the desired specifications in terms of quality, functionality, and appearance. Here’s a detailed overview of these steps:

1) Concept and Design

Requirements Analysis: at the beginning phase, our team communicate with client to understand the client’s needs, product specifications, and functional requirements. Engineers and designers then conduct feasibility study of the design from aspects of material, geometry, and production.

Design Development: at this stage, our team create detailed 3D models using Computer-Aided Design (CAD) software. These designs are reviewed to identify potential issues and ensure the design meets all requirements.

2) Prototyping

Then we fabricate the prototype. Prototype for initial evaluation validates the design and helps identify issues not found in design. Prototype can be made combination of different methods, like 3D printing and CNC machining.

Prototype is also for functional testing to ensure it meets functional requirements and make any necessary adjustments to the design.

3) 3D Mold Design

At this step, we start to design detailed mold.

- Mold Flow Analysis: Use simulation software to analyze how the molten plastic will flow into the cavities of the mold, identifying potential issues like air traps or weld lines.

- Final Design: Develop the final mold design, including all details such as gates, runners, and cooling channels.

4) Mold Fabrication

Select proper material for relative project and demand.

- Choose Mold Material: Select high-quality materials like steel or aluminum based on the production requirements and expected mold lifespan.

Fabrication and shaping. - CNC Machining: Use CNC

- machines to precisely cut and shape the mold components.

- EDM: Employ wire-electrode cutting, Electrical Discharge Machining (EDM) for intricate details and fine geometries.

5) Mold Testing and Adjustment

Trial Runs. After mold is fabricated, a small trial run will take place to validate the mold.

- Initial Mold Testing: Conduct trial runs with the new mold to produce sample parts.

- Inspection and Adjustment: Inspect the sample parts for defects or dimensional inaccuracies and make necessary adjustments to the mold.

6) Production Setup

Machine Preparation. Before a production run, machines need setup for specific production need.

- Injection Molding Machine Setup: Prepare the injection molding machine by setting the appropriate parameters such as temperature, pressure, and cycle time.

- Material Preparation: Ensure the selected plastic material is available and properly prepared for injection.

7) Injection Molding Process

- Melting: Heat the plastic pellets loaded in the injection molding machine until they melt for flowing into mold in next step.

- Injection: Inject the molten plastic into the mold cavity with high pressure.

Cooling and Solidification. - Cooling: after molten plastic injected into mold cavity, it needs cooled down for form geometry. By cooling system of the injection machine, molten plastic is solidified and formed.

Mold Opening and Ejection

When molten plastic is solidified in the mold cavity and formed, it needs to eject out from the mold.

- Mold Opening: this is controlled by preset program for the injection machine.

- Part Ejection: formed part is pushed out by ejector pin or other mechanisms from the mold.

8) Post-Processing

Part from the mold usually need further treatment as following:

- Trimming: Remove any excess material, such as sprues or flash, from the parts which is removed out of the mold.

- Surface Finishing: some part may need surface treatments, such as painting, texturing, logo printing, or coating.

- Component Assembly: If the final product consists of multiple parts, assemble them as required.

9) Product Assembly

At Batnon, our product assembly services are there to seamlessly integrate with our comprehensive production process. From single components to complex assemblies, we ensure each product is meticulously assembled to meet your exact specifications. Our skilled technicians and advanced assembly techniques guarantee high-quality, reliable products delivered on time.

10) Quality Control

- Inspection

• Finish and coloring check.

• Dimensional Inspection: Use measuring tools to validate that parts meet dimensional specifications. - Functional Testing: Perform functional tests to ensure the parts function as intended.

Quality Assurance

• Documentation: File up inspection results and maintain records for quality assurance purposes.

11) Packaging and Delivery

- Product Packaging

Packaging: Package the finished parts according to the client’s specifications, ensuring they are protected during transportation. - Delivery

Shipping: Arrange for the delivery of the finished products to the client’s location, ensuring timely and secure shipment.

Conclusion:

The journey from mold design to final production involves a series of meticulously planned and executed steps. Each stage is crucial in ensuring the production of high-quality plastic parts that meet the client’s specifications and industry standards. By following this comprehensive process, manufacturers can achieve precision, efficiency, and consistency in their injection molding operations.

6. Types of Materials for Plastic Injection Molding

At Batnon, we understand that selecting the right material is crucial for the success of your project. We offer a wide range of high-quality plastic materials to meet the diverse needs of our clients. Each material has unique properties that make it suitable for specific applications. Here’s an overview of the types of materials we use for plastic injection molding:

Type 1: Thermoplastics

- Polyethylene (PE), including LDPE and HDPE.

• LDPE stands for Low-Density Polyethylene: LDPE features for its flexibility and resilience, LDPE is commonly used in packaging, plastic bags, and containers.

• HDPE stands for High-Density Polyethylene: HDPE has higher strength and rigidity, making it ideal for products like bottle caps, crates, and piping. - Polypropylene (PP)

• This is lightweight material, it has good resistant performance under chemical environment, its melting point is higher than other kinds.

• Applications: Automotive parts, reusable containers, medical devices, and consumer goods. - Acrylonitrile Butadiene Styrene (ABS)

• This is widely used and popular material that can be found in many application and products. It features of high impact resistance, toughness, and easy machining.

• Applications: Electronic housings, automotive trim, toys, and household appliances. - Polystyrene (PS)

• Properties: Rigid and inexpensive, available in both solid and foam forms.

• Applications: Disposable cutlery, CD cases, and packaging materials. - Polycarbonate (PC)

• Properties: Extremely durable, impact-resistant, and has high optical clarity.

• Applications: Safety glasses, optical disks, automotive headlamp lenses, and electronic components.

Polyvinyl Chloride (PVC)

• Properties: Strong, durable, and resistant to environmental degradation.

• Applications: Plumbing pipes, medical tubing, cable insulation, and window frames.

Type 2: Engineering Plastics

- Polyethylene Terephthalate (PET)

• Properties: High strength, chemical resistance, and excellent dimensional stability.

• Applications: Beverage bottles, food containers, and automotive parts. - Polyamide (Nylon)

• Properties: Excellent mechanical properties, wear resistance, and low friction.

• Applications: Gears, bearings, and automotive components. - Polyoxymethylene (POM or Acetal)

• Properties: High stiffness, low friction, and excellent dimensional stability.

• Applications: Precision parts like gears, fasteners, and automotive fuel systems. - Thermoplastic Elastomers (TPE)

• Properties: Combines the properties of rubber with the recyclability of thermoplastics.

• Applications: Soft-touch grips, seals, gaskets, and flexible connectors.

Type 3: High-Performance Plastics

- Polyether Ether Ketone (PEEK)

• Properties: Outstanding mechanical properties, chemical resistance, and high-temperature performance.

• Applications: Aerospace, medical implants, and high-performance automotive parts. - Polysulfone (PSU)

• Properties: High-temperature stability, chemical resistance, and toughness.

• Applications: Medical devices, plumbing fittings, and electrical components.

Choosing the Right Material

Selecting the appropriate material depends on various factors, choose it based upon the following aspects: the intended application, environmental conditions, mechanical requirements, and cost considerations. Our team of experts is here to help you choose the most suitable material for your project, ensuring optimal performance and durability.

Contact Us

If you have any questions about the materials we use or need assistance selecting the right plastic for your project, please contact us. At Batnon, we are committed to providing you with high-quality materials and exceptional service to meet all your plastic injection molding needs.

7. Industries We Serve with Our Plastic Mold and Injection Services

At Batnon, our plastic mold and injection services cater to a wide range of industries, providing high-quality, precision-engineered parts and products. Here are some of the industries we serve:

Automotive

- Components: Dashboards, interior trim, door handles, air vents, and fluid reservoirs

- Benefits: High precision, durability, and the ability to produce complex geometries.

Electronics

- Components: Housings, connectors, switches, and circuit board components.

- Benefits: High-quality finishes, intricate detailing, and material options for electrical insulation.

Medical Devices

- Components: plastic parts for diagnostic equipment and surgical instruments

- Benefits: High precision, biocompatibility, and adherence to stringent regulatory standards.

Consumer Goods

- Products: Household items, toys, kitchenware, and personal care products.

- Benefits: Versatility in design, color, and material options to meet diverse consumer needs.

Packaging

- Products: containers, and custom packaging solutions.

- Benefits: High-volume production, lightweight, cost advantage

Aerospace

- Components: Aircraft interior parts, chair components, handles, and structural elements.

- Benefits: High strength-to-weight ratio, precision, and resistance to extreme conditions.

Construction

- Components: Plumbing fittings, insulation components.

- Benefits: Durability, resistance to environmental factors, and ease of installation.

Telecommunications

- Components: Enclosures, connectors, buttons, and cable management solutions.

- Benefits: High precision, durability, light weight

Industrial Applications

- Components: Gears, shafts, housings, machine components, and tools.

- Benefits: High durability, precision, and ability to withstand harsh environments.

Agriculture

- Components: Irrigation system parts, equipment housings, and farm machinery components.

- Benefits: Durability, resistance to UV exposure, and cost-effectiveness.

Renewable Energy

- Components: Solar panel mounts, and battery housings.

- Benefits: High strength, weather resistance, and precision engineering.

Contact Us

if you have specific requirements, please contact us. At Batnon, we are dedicated to providing tailored plastic mold and injection services to meet the unique needs of our clients across various industries.

8. Quality Assurance in Plastic Mold and Injection Process

At Batnon, quality is at the core of our plastic mold and injection molding process. We are committed to delivering products that meet the standards of precision, durability, and functionality performance. Here below details what measures we employ to ensure exceptional quality throughout our production process:

1) Material Quality Control

- Raw Material Testing: We begin by rigorously testing all incoming raw materials to ensure they meet the required specifications and quality standards.

- Material Certification: We use certified materials from reputable suppliers to guarantee consistency and reliability.

2) Mold Design and Fabrication Quality Control

- Precision Mold Fabrication: Our molds are designed with advanced CAD software and fabricated with state-of-the-art technology and equipment, like CNC machines, wire-electrode cutting, EDM, to achieve tight tolerances and intricate details.

- Prototype Validation: Before full-scale production, we create prototypes and conduct thorough testing to identify and resolve any design issues.

3) In-Process Quality Control

- First Article Inspection (FAI): We perform detailed inspections on the first parts produced to verify that they meet all specifications and quality requirements.

- In-Process Inspection: Continuous inspection during production ensures that any deviations or defects are promptly identified and corrected.

- Advanced Sensors for real time monitoring: Our injection molding machines are equipped with sophisticated sensors that monitor critical parameters such as temperature, pressure, and injection speed in real time.

4) Post-Production Quality Assurance

- Dimensional Verification: We use precision metrology tools and techniques, such as coordinate measuring machines (CMM), and calipers, to verify that the final parts meet all dimensional requirements.

- Functional Testing: Depending on the application, we conduct functional tests to ensure the parts perform as intended under real application conditions.

5) Surface Finish and Appearance

- Visual Inspection: Our quality team inspects the surface finish and appearance of each part to ensure they meet the aesthetic standards required by our clients.

- Defect Remedy: Any parts with cosmetic defects or inconsistencies are identified and addressed before packaging.

6) Lean Manufacturing for Continuous Improvement

- Efficiency Enhancement and Waste Reduction: We employ lean manufacturing principles to continuously improve our production practice, reduce waste, and enhance overall efficiency.

- Employee Training: Our team undergoes regular training to stay updated on the latest quality assurance practices and technologies.

7) Compliance and Certification

- ISO Standards: Our quality management system is aligned with ISO standards, ensuring we stick to internationally recognized best practices.

- Regulatory Compliance: We comply with all relevant industry regulations and standards to meet the specific needs of various sectors, including automotive, medical, and aerospace.

8) Customized Quality Plans for Customer Satisfaction

- Tailored Solutions: We work closely with our clients to develop customized quality assurance plans that address their unique requirements and expectations.

- Feedback and Collaboration: We value client feedback and collaborate with them so that we can continuously improve our processes and products.

9) Reliable Delivery

- On-Time Delivery: Our efficient production processes and rigorous quality assurance measures ensure that we deliver high-quality products on time, every time.

- Consistent Quality: Our commitment to quality assurance guarantees that every batch of products meets the same high standards, ensuring customer satisfaction and trust.

What We Will Take for Your Plastic Mold and Injection?

If you have any questions about our quality assurance process or would like to learn more about how we ensure quality in our plastic mold and injection services, please contact us.

9. Design Assistance, Engineering Support, and Prototyping Services

At Batnon, we offer a comprehensive suite of services to bring your ideas from concept to reality with precision and efficiency, These services cover all phases in your demand realization process.

1) Design Assistance

Our design assistance services help you visualize your concept into detailed, manufacture-viable designs. Our design team works closely with you for:

- Concept Development: Collaborate on initial ideas and refine them into viable product concepts.

- 3D Modeling Creation: Create precise 3D models using advanced CAD software, ensuring every detail meets your specifications.

- Design Optimization: Enhance designs for functionality, aesthetics, and manufacturability, considering factors like material selection and production processes.

2) Engineering Support

Our engineering support ensures that your project benefits from expert insights and technical proficiency. These include:

- Product Feasibility Study: Assess the technical feasibility of your designs, mold fabrication and production, identifying potential challenges and solutions.

- Material Selection: Recommend the best materials based on your product’s requirements, ensuring optimal performance and cost-effectiveness.

Mold Flow Analysis: use simulation analyzing tools to simulate molten plastic flowing in the mold, take according optimization on the design for best quality and efficiency. - Process Optimization: improve manufacturing processes to enhance product quality, shorten cycle time, reduce production costs.

3) Prototyping Services

Our prototyping services allow us to test and refine your designs before full-scale production.

Our prototyping services include:

- Rapid Prototyping: Fast make prototypes using 3D printing, CNC machining, and other methods to validate designs and make adjustments if needed.

- Functional Test: Perform thorough testing on prototypes to ensure they meet all functional and performance need.

- Iterative Development: Work through multiple prototype iterations to perfect your product design, pursuing best version for mass production.

How we can help in your project?

Partner with Batnon for expertise assistance, engineering support, and prototyping services that bring your ideas to reality with precision and reliability. Contact us to learn more about how we can help you achieve your project goals.

10. Success Case Study

Client Industry: Auto Repacking

Project Overview:

the client, a leading supplier of performance auto parts, approached Batnon with a critical project: the development of a new, high-precision dashboard assembly for a latest vehicle model. The project required intricate design work, high-quality materials, and rigorous quality control to set up the standard for the auto performance industry.

Challenges:

- Complex Design Requirements: The dashboard assembly featured a complex design with tight tolerances and multiple integrated components.

- High-Volume Production: the project required a reliable partner capable of producing large volumes in consistent quality.

- Material Specifications: The materials had to meet stringent automotive standards for durability, aesthetics, and safety.

Our Solutions:

1) Design Assistance and Engineering Support

- Collaborative Design Development: Our design team worked closely with client’s engineers to refine the dashboard assembly design, ensuring it’s mold fabricability, production viability, and met all functional and aesthetic requirements.

- Advanced CAD Design: We utilized advance CAD design software to create detailed 3D models, allowing for precise visualization and adjustments.

- Material Selection: We recommended a high-impact, UV-resistant, and reinforced by adding additives, thermoplastic to ensure durability and long-term performance.

2) Prototyping and Testing

- Rapid Prototyping: We produced several prototype iterations using 3D printing and CNC machining, enabling client for reviewing and validating the designs quickly.

- Functional Testing: Each prototype underwent rigorous testing for fitting, finish, and performance, ensuring product made with the final design met requirement

3) Mold Fabrication:

Our skilled technicians fabricated high-precision molds using advanced CNC and EDM technology, ensuring tight tolerances and intricate details.

4) Injection Production:

We implemented a highly efficient injection molding process, with real-time monitoring and automated quality control to maintain consistency across high-volume production.

5) Quality Assurance:

Every batch of components underwent thorough inspection, including dimensional check and functional testing, to ensure they met client’s exacting standards.

Results:

1) Successful Product Launch: The new dashboard assembly was successfully put on shelf, symbolizing a seamless launch.

2) High-Quality Production: We delivered over 100,000 units with zero defects, meeting client’s high standards for quality and performance.

3) Cost and Time Efficiency: Our optimized processes and efficient production capabilities resulted in significant cost savings and on-time delivery.

Client Testimonial:

“Batnon exceeded our expectations in every aspect of this project. Their expertise in design, engineering, and production ensured our new dashboard assembly met the highest standards of quality and precision. We couldn’t be happier with the results and look forward to continuing our partnership.”

— John Frayer, Product Manager, Automotive Solutions

Conclusion:

This success case study demonstrates Batnon’s ability to tackle complex projects and deliver high-quality plastic mold and injection services. Our commitment to precision, quality, and customer satisfaction ensures we can meet the most demanding requirements of the industry and beyond.

For more information on how Batnon can assist with your plastic mold and injection needs, please contact us. We are enthusiastic to turning your ideas into reality with excellence and efficiency.

11. How to Request a Quote?

At Batnon, we aim to make the quote request process as simple and efficient as possible. Whether you have a fully developed design or just an initial concept, our team is here to assist you every step of the way. Follow these easy steps to request a quote:

Steps to Request a Quote

1. Contact Us

- Online Form: Fill out our online request form available blow of this page. Provide basic details about your project to help us understand your needs.

• Email: Send your project details to sales@batnon.com , and one of our representatives will get back to you promptly. - Phone: Call us at +86 136 62620926 to speak directly with a member of our team. We’re available during business hours to assist.

Skyp - e: our ID for Skype is “wrineliang”

- Whatsapp: +86 13662620926

- Wechat: creationdone

2. Provide Project Details

- Project Description: Include a brief overview of your project, such as the type of product, its intended use, and any specific requirements.

- Design Files: If available, upload design files (best in .STEP format) to give us a detailed understanding of your project.

- Material Preferences: Specify any preferred materials for your product. If you’re unsure, our team can recommend the best options based on your requirements. Please include finish and coloring if needed.

- Quantity: Indicate the expected production volume, whether it’s a prototype, a small batch, or a large-scale production run.

3. Consultation and Review

- Initial Consultation: Our team will review your project details and may contact you for additional information.

- Technical Review: Our engineers will analyze your design files, material specifications, and production requirements to ensure feasibility and accuracy.

- Quotation Preparation: Based on the information provided, we will prepare a detailed quotation that includes cost estimates, production timelines, and any additional services required.

4. Receive Your Quote

- Detailed Quote: You will receive a comprehensive quote outlining all aspects of your project, including costs, timelines, and any additional services.

- Project Plan: Along with the quote, we will provide a proposed project plan to give you a clear understanding of the process from start to finish.

5. Review and Approve

- Quote Review: Take the time to review the quote and project plan. Our team is available to answer any questions or make adjustments as needed.

- Approval: Once you are satisfied with the quote, provide your approval, and we will begin the next steps to kick off your project.

Why Choose Batnon?

- Expertise: Our experienced team offers exceptional design assistance, engineering support, and high-quality production.

- Customization: We tailor our services to meet your specific needs, ensuring your project is a perfect fit.

- Efficiency: Our streamlined processes and advanced technologies guarantee timely delivery and cost-effective solutions.

- Quality Assurance: We adhere to strict quality control measures to deliver products that meet your requirements.

Get Started Today

Ready to bring your project to life? Contact us today to request a quote for our plastic mold and injection services. Fill out the “Request a Quote” form as below, email us at sales@batnon.com , or call us at +86 136 6262 0926, or through Skype/Whatsapp/Wechat. At Batnon, we’re committed to providing you with exceptional service and high-quality results.

Manufacture Services

Inquiry or Question? We love to hear from you!

For inquiry or questions, please send your message, we’ll respond shortly.