We Enable Startups to Scale Reliably with Our Precision Manufacturing

36 Years | Total 921,182 Sqft | 2500 Staff | 600+ Machineries | 500,000 Monthly Output

A Hidden Supply Backer Behind Over 200 Well-Known Branding Companies Who’re Active at the Forefront

Downing Your Overall Cost By 40% +

Get a Fast Quote to See How We Do It

Our Manufacturing Capabilities

3/4/5 axis CNC manufacturing center for making precision parts, metal, plastic and wood.

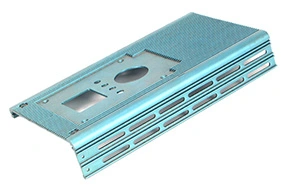

Sheet Metal

Custom sheet metal fabrication, cutting, bending, stamping, and forming, combined with versatile surface treatments and engineering analysis to ensure both manufacturability and cost efficiency.

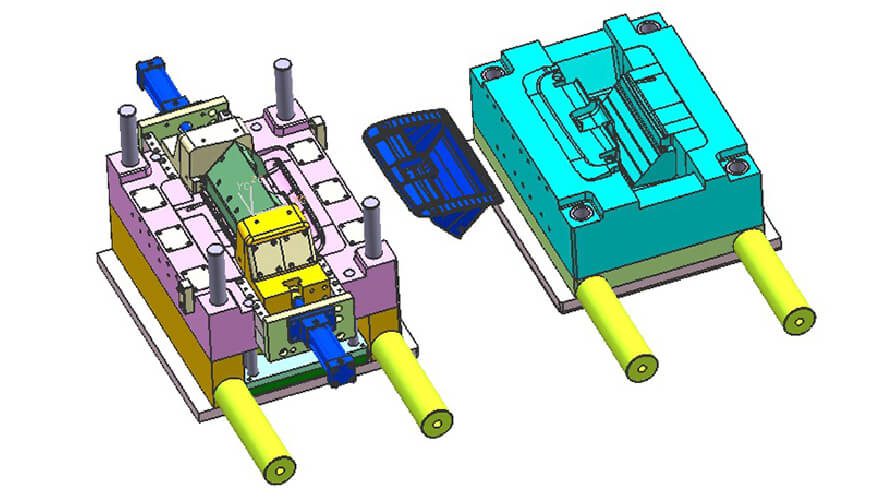

Fast mold fabrication, precisely molded, bringing your ideas to life with unmatched quality, flexibility, and speed

High precision plastic injection molding, equiped with a 780-ton injection machine for super large injection molded part.

Extrusion

Innovative extrusion profiles tailored to your needs—precision-engineered, customizable designs with exceptional strength, seamless finishes, and fast, reliable delivery.

Finishing and Coloring

Premium surface treatment solutions to enhance durability, aesthetics, and performance for metal parts, plastic parts, and rubber parts.

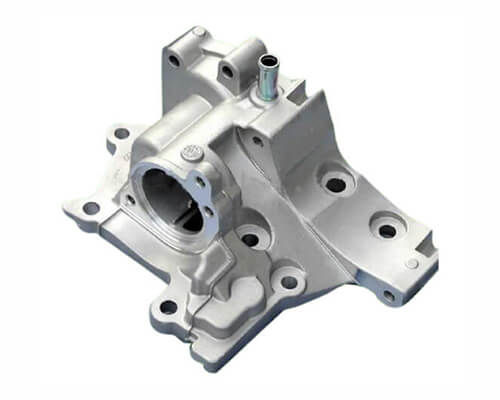

Materials include aluminum, iron, s.steel, zinc alloy, applied for mechanical, equipment, machinery, and electronics industries.

Experience precision and versatility with our 3D printing services manufacturing custom designs, rapid prototyping, and high-quality production for everything you need.

Assembly

Our product assembly service finalizes the last step before your products hit the market. Shorter time, Lower costs.

921,182

Factory Space sqft²

2526

Staff

600+

Machinery | Equipment

242

QC Staff

181

Engineers

18,000

Daily Output pcs

<0.1%

Defective Rate

>99.8%

Delivery On Time

36years

Duration of establishment

Industries We Serve

Automobile

High-precision components, custom parts, and prototyping for automotive systems and vehicles to ensure durability and performance.

Energy

Durable, high-quality parts for renewable energy systems, power generation equipment, and energy storage solutions.

Aerospace and Aircraft

Precision manufacturing of lightweight, durable parts for aircraft systems, ensuring performance and compliance with strict regulations.

Food and Beverage

Fabrication of food-grade machinery components, ensuring hygiene, durability, and compliance with safety standards.

Automation

Custom-machined parts for automated systems, including robotics, conveyors, and industrial automation solutions.

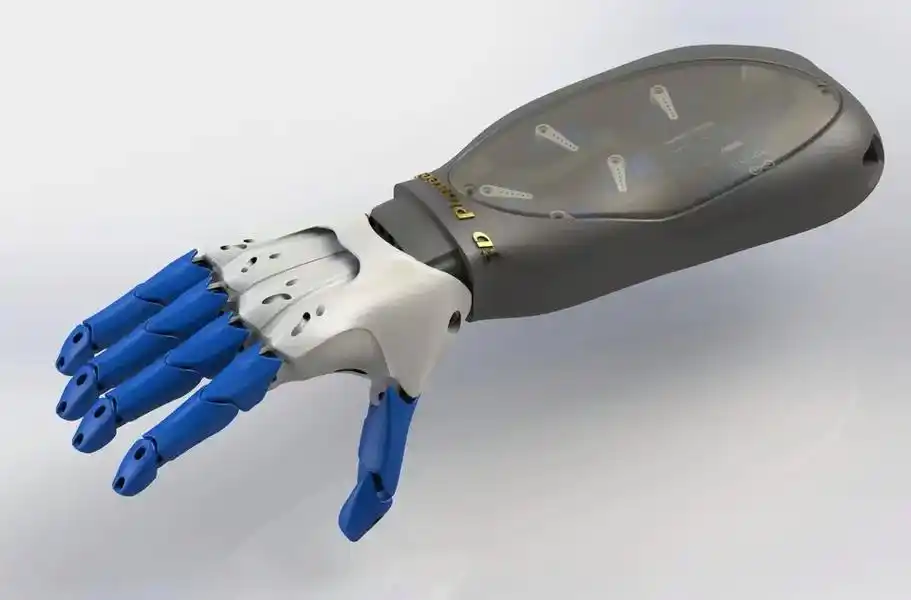

Robotics

Customized components for robotic systems, enhancing functionality and reliability across industrial and service applications.

Electronics

Custom solutions for consumer products, offering design flexibility, prototyping, and production for diverse applications.

Machinery & Equipment

Custom components for industrial machinery, ensuring precision, durability, and high-performance operation.

Medical

Manufacturing precision components for medical devices, tools, and equipment that meet industry standards and certifications.

Electrical

Production of enclosures, connectors, and components for electrical systems ensuring safety and efficiency.

Consumers

Custom solutions for consumer products, offering design flexibility, prototyping, and production for diverse applications.

Printing

High-precision parts and custom tools for printing machinery to enhance operational efficiency and output quality.

78“ x 48″ x 23″

2032x1219x610mm

Max Size For Milling

60″ L x 32″ Dia

1524 x D 812mm

Max Size For Turning

Chamfering

Filleting

Edge & Corner

±0.0000079″

±0.002mm

Precision Tolerence

Guarantee:

Satisfaction or Refunding

Why Choose Us for Your New Projects?

A Reliable Partner that’s Trustworthy.

Substantial Cost Reduction Guaranteed

Through seamless coordination across all processing stages and unwavering commitment, we ensure significant cost savings that safeguard your projects.

Trustworthy with 26 Years of Excellence

With a robust 26-year history of serving over 5000 customers worldwide, we are dedicated to delivering unmatched quality and reliability.

Efficiently Minimizing Project Time

We meticulously review every process step to eliminate delays and optimize details, ensuring substantial reductions in overall project duration.

Streamlined Workflow Visibility

Get an online quote within 12 hours of inquiry, and stay updated with real-time order status through video and photo updates of the production process.

36 Years of Industry Expertise

Drawing on our extensive 26-year track record, we leverage deep engineering capabilities and experience in handling complex projects with precision.

Quality and Refund Guarantee

We stand by our commitment to quality with a comprehensive guarantee. From meticulous material selection to rigorous in-process inspections and final product delivery, we ensure every aspect meets your predefined standards or your money back.

What They Say

A fantastic metal working company, 10/10 customer service and fantastic value… I would highly recommend for custom motor prototype parts

Mr. Sean O’Brien

Manager Director

I LOVE the door openers. They look great and appear to be of high-quality. I have already told some of my friends about your company. Hopefully, they will also place orders with you. I look forward to doing business again. You were very responsive and professional. A real joy to work with.

Edward Zeidan

CEO

The parts were checked and are all good,I like the finish and packing over all good quality,we are happy with your work. Please convey it to your team.look forward in working with you in future also.

Cathal Barber

Owner

Lean production

We continually optimize our production methods and human organization to enhance overall management and factory efficiency, maximizing our potential for both productivity and time saving.

Visualization System

We have designed a comprehensive process and developed specialized software allowing us for easy and quick viewing of each product’s or project’s progress through photos and videos, ensuring transparency and efficiency.

Automation

Our automated production processes not only reduce costs but also create conditions for improving and maximizing resource potential. This leads to enhanced product quality and overall efficiency.

Advanced Technology

We employ the latest technology and state-of-art machinery in network communication to enhance human-machine interaction and machine-to-machine cooperation, ensuring seamless and efficient operations.

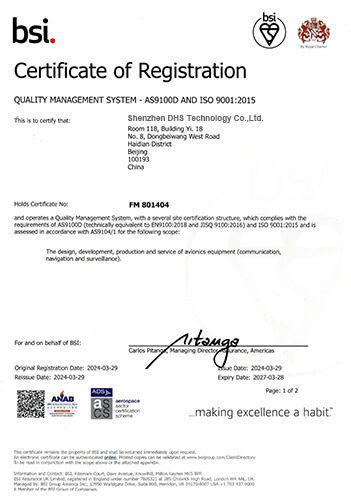

Quality Management System

Our commitment to quality is unwavering. Our Quality Management System (QMS) ensures that every product meets the highest standards of excellence. This QMS include:

- Comprehensive Quality Controls: Stringent inspections and testing throughout production to ensure precision and reliability.

- Continuous Improvement: Continuous improvement, regularly updating our processes.

- Skilled Team: Experienced professionals are dedicated to maintaining quality at every stage of the manufacturing process.

With our robust QMS, we deliver products that exceed expectations and stand up to the highest industry standards.

ISO 9001:2015

AS9100 Certificate

IATF16949 Certificate

ISO13485 Certificate

As a precision machining company, at Batnon, our CNC machining services provide precision and efficiency for your custom metal and plastic parts. Utilizing state-of-the-art CNC technology, we cater to a wide range of industries, delivering high-quality, accurate components with rapid turnaround times. Our skilled team ensures each part meets exact specifications, from prototyping to full-scale production. With capabilities to handle complex geometries and tight tolerances, we excel in producing both small and large-volume orders.

Whether you need parts for aerospace, automotive, medical devices, or consumer electronics, Batnon is your trusted partner for all CNC machining needs. Experience unparalleled quality and reliability with our comprehensive CNC solutions.

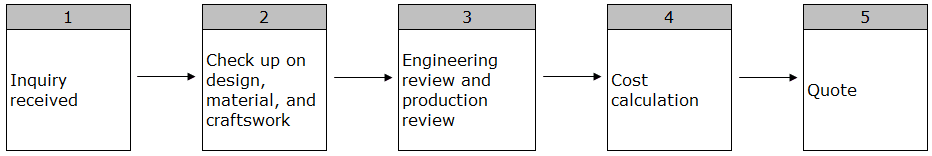

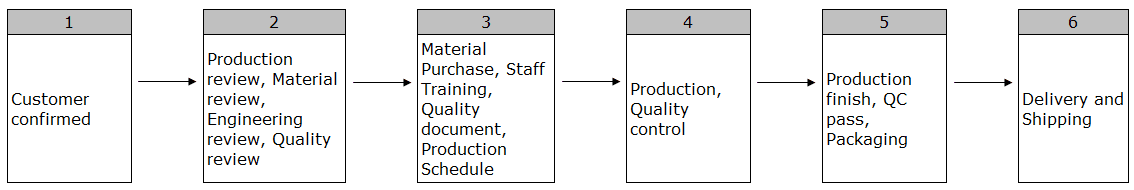

Service Procedures

STEP 1

Design files in .step / .dxf / .pdf format by email or online

STEP 2

Engineering review, DFM

STEP 3

Quote for sampling, unit price, production lead time, and freight if required

STEP 4

Order confirmation and Manufacturing

STEP 5

Delivery and shipping through express / air / sea.

STEP

IGES

X_ T

DWG

DXF

Metal

Aluminum alloy

Magnesium

Brass

Titanium

Copper

Tool Steel

S.Steel

Zinc Alloy

Steel

Spring Steel

Carbon Steel

Tungsten

Plastic

Acrylic

Polycarbonate

PVC

Delrin

Polypropylene

Torlon UHMW

Acrylic

PPS

Ultem

Garolite G-10

PTFE

HDPE

PVC

РЕЕК

PTFE

Others

Wood

Bamboo

Rubber

Silicone