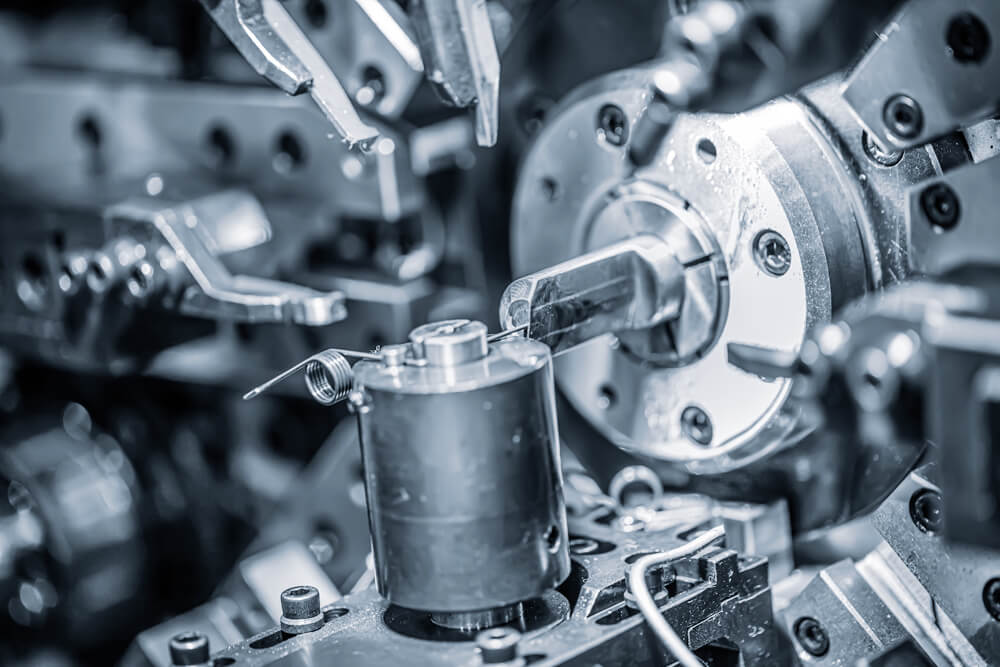

When outsourcing a precision CNC machining part, we often care how the CNC machining tool precision is. In reality, some factors need to consider in achieving a high precision level.

1. Position error

Position error refers to the change or deviation degree of the mutual position between the actual surface, axis or symmetry plane of the machined part compared with its ideal position, such as perpendicularity, position degree, symmetry degree, etc.

The position error in CNC machining usually refers to the dead zone error. The main causes of position error are the machining error caused by the gap and elastic deformation during machining, and the position error caused by the friction of the tool head in machining.

In the open-loop system, the position precision is greatly affected, while in the closed-loop servo system, it mainly depends on the accuracy of the displacement detection device and the speed amplification factor of the system, which is generally less affected.

2. Geometric error

In the process of NC machine tool machining, due to the influence of external factors such as external force and heat generated in the process, the geometric precision of the machine tool is affected, and the parts processed on the machine tool produce geometric deformation, resulting in geometric error.

According to the research, there are no more than the following two main reasons for the geometric error of CNC machine tools: internal factors and external factors.

The internal factors of geometric errors of machine tools refer to the geometric errors caused by the factors of machine tools, such as the levelness of the worktable, the levelness and straightness of the guide rails, the geometric accuracy of the cutting tools and fixtures, etc.

External factors mainly refer to the geometric errors generated under the influence of external environment and thermal deformation in the process of machining.

For example, in the process of cutting, due to thermal expansion and deformation of cutting tools or parts, geometric errors are generated, which affect the machining accuracy of machine tools and parts.

3. Machine positioning

Through the long-term data analysis and practical operation of parts processing, it can be seen that machine positioning has a great impact on the machining precision of CNC machine tools.

From the structure point of view, the machining errors of CNC machine tools are mostly caused by the positioning accuracy, and the feeding system of the machine tool is the main link affecting the positioning accuracy.

The feeding system of CNC machine tool is usually composed of mechanical transmission system and electrical control system. The positioning precision is related to the mechanical transmission system in structural design.

In the closed-loop system, CNC machine tools usually can prevent the position deviation of the main parts in the feeding system, such as ball screw, by positioning detection device.

For the open-loop system, because of many factors and complex situation, it is unable to carry out positioning monitoring, so it has a great impact on the machining accuracy of CNC machine tools.