During the years we served thousands of creators / innovators coming to us with fantastic designs, which reflect their ideas for changing something. For each one, we, as a manufacturing partner, are always proactive and eager to help and do something in their journey. That’s not only motivated by business opportunities, but also out of a sense of inherent responsibility.

Therefore, I watched, experienced, and attended many cases and saw their up-and-down, from a close distance and a special view angle, as an observer and participant. For those being successfully launched and growing up, we can feel and enjoy the tangible positive results. While for those less fortunate, their voices faded gradually silently until they could no longer be heard, leaving a mess of unfinished redesigns, untested 8th-loop prototypes, unreplied supplier emails, ignored customer calls, and the bank account reduced to zero…

I wrote this piece not to educate, but to inspire thought: what are factors leading to success and failure, what should be avoided in hardware creation journey.

The purpose of this work is to provide guidance that might be helpful at the time you’re planning your own creative journey.

Understand the Truth:

There’s statistics that hardware creation success rate is not higher than 10%, failure no less than 90% CB Insights Report and MacroFab analysis.

Cruel, isn’t it?

For what reasons do those fall?

- funding?

- competition?

- manufacturing?

- technical hurdles?

After long years of watching and real experiences, I realize the answer is not so simple and superficial. It’s rooted in a dark and hidden area, which can only be discovered by careful observation over time.

From the eyes of someone in manufacturing industry, this is not to analyze or reason logically, but patterns or reality concluded from different specific cases and common traits found among them.

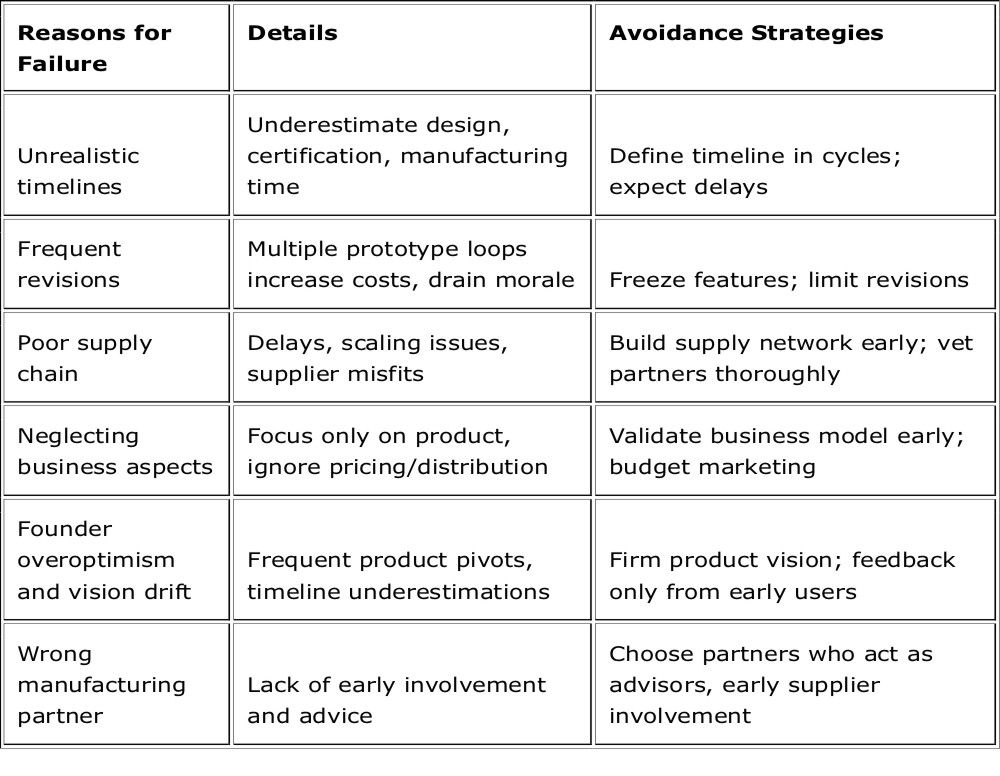

1) Unrealistic judgement of time frame

You set up the whole project and break them down to segments, each one with a specific number of days to go:

electronics, hardware, mechanical designs: 14days prototype: 21days test and validation: 7days design modification: 14days 2nd prototype loop: 21days retest and revalidation: 7days

When it’s in process, you’ll find a small slow-down or deviation will break the schedule. You have to rewrite the timeline on your project management board again and again.

When you experience this more than three time, you’d get used to such change.

What’s wrong with your timetable?

Nothing.

This is how things really go in the real world.

The timetable is a reflection of your idealism and perfectionism.

It’s time for you to see the reality.

Date for reference:

- most creators underestimate overall timeline by 2x or 4x

- underestimate certification timeline by 3x

- underestimate manufacturing difficulty by 10x

In reality, when timeline is broken, two results come along the way:

- cash burning accelerating

- investor confidence and passion dropping

It worsens when the two intersect. That’ll push the project closer to failure.

Truth is creators need 3 cycles to learn and be good at setting up timelines with a realistic mindset.

2) Revision – another killer for budget drain

You surely won’t foresee so many changes / revisions after you start prototyping, along the way through to engineering sampling, pilot run sampling, and production sampling. These engineering changes will bring anything you won’t predict or imagine during planning stage.

These revisions will consume your patience, enthusiasm, perseverance… They will weaken your team morale, They will quickly drain your budget in a visible manner.

Revision is such a ghost waiting on the road of your journey, smiling and waving, friendly and malicious.

Many don’t realize they will endure 3-8 prototype loops, Each loop increased prototype cost 15-40%, Mechanical parts cost increased by 40% or more, Electronics cost increases by another 30%

Take an example: from you need to change a connector → PCB changes → enclosure changes → tooling changes → schedule collapses → more cost.

If you have to add a new sensor → new firmware → power redesign → new EMC failure → more redesign.

What you’ve seen in the revision chain is increased cost.

You may feel uneasy considering those increased costs. A compromising thinking mode breeds in your brain.

- looking for lower pricing parts.

- skipping reliability testing

- skipping some certification

- removing some features to reduce cost

- change supplier temporarily for lower pricing

- force current supplier to find a cheaper solution

You might ignore an inner warning voice and let things move on.

3) Temporary supply chain network building

There is no correct or incorrect time for when to build a supply chain network. But the best way is the earlier, the better.

You need a long time of communication with supplier to identify if they’re the right one for you.

It’s not just about pricing, which is merely an aspect of supplier evaluation.

- Is communication smooth?

- Can you both sides easily understand each other?

- Will one side consider something unspoken by the other side in making decision?

- Except business negotiation, can the other discuss directly technical and engineering points with you with no other people’s help?

- Is the response timely or after a long time?

Someone who always can not catch up with you will eventually frustrate you. On the other hand, a good communicator will bring ease and good feeling while mutual understanding is reached.

What will you consider when selecting someone to be your supplier besides communication?

- more convenient?

- lower pricing?

- relative or friend’s introduction?

- local source?

You find someone to make your prototype and pilot run, small batch 100pcs, 200pcs, all seems OK.

But once you require 500pcs, 1000pcs, 5000pcs, they fail.

You may wonder what’s wrong when it scales?

McKinsey’s 2023 survey(McKinsey Report on Hardware Startups):

- 67% of hardware startups fail during scaling

- 52% of delays come from supplier-side issues

- teams underestimate lead time by 30–70%

Startup creators build the supply chain this way:

- Design first

- Prototype

- Find supplier

- Adjust design

- Run into problems

- Change supplier

- Redesign again

They will hand some most important job to someone with no long-time communication and verification for their processing capabilities, quality, manufacturing, engineering, packaging and packing, shipping and logistics.

In other words, they give the work to someone they actually don’t understand, while they understand technical and materials so well.

Those succeeding will do it another way:

- involve suppliers early

- design with manufacturability in mind

- let manufacturing experts highlight risks

- simplify the BOM early

- commit to stable partners

Good supplier dose not come right when you need. It’s something that you’ve spent a long time to build a network intentionally and strategically.

4) Building a product without building a business

This is so commonly found.

Project teams put their most energy and time on building the tangible product, while neglecting the product serving another purpose: a business.

The business that includes not only the product, the people in the office, supply chains, channels and distributors, marketing partners, sales platforms, KOLs(Key of Leaders), customers, and other associates who are involved in the projects.

Product is not business, business needs product.

While we can often see teams spend:

- 90% on engineering

- 10% on marketing

- 0% on pricing

- 0% on distribution

- 0% on long-term cost structure

When the product is ready for market, they find:

- customer acquisition cost soaring

- return cost so high

- marketing fees exceeding expectation

- Ads cost running at an unacceptable level

- logistics fees greatly shrinking margin

- every corner around product cutting profits

A dataset from Hardware Club shows:

- 58% ran out of cash because of wrong pricing

- 37% never reached market due to no distribution plan

- 26% built something the market didn’t want Hardware Club Report

Your engineering expertise brings the product to the world.

Business decides whether it can exist in the world.

5) Creator’s overoptimism, overconfidence, vision drift

It’s popular to hear from creators:

- hardware founders are 2.4x more optimistic than software.

- 70% founders believe their product will be shipped in 12 months.

- 68% change product direction at least 3 times.

Every time direction changes will cause a new setup for everything:

- design

- engineering validation

- prototype and test

- supplier reverification

- BOM

- cost update

- timeline update

Vision drift is a real threat to any product realization.

6) Wrong manufacturing partner

There’s no absolute best, there’s only a relatively best fitting.

Different companies at their specific development stage find the best partners who can meet their specific standards.

For startups, the best ones are those who can provide constructive suggestions on processing ways, materials, optimized engineering solutions, suitable tolerances, adaptive cost structure…, they can provide suggestions beyond just saying Yes, and they actually:

- push back on impossible tolerances

- warn you about exploding costs

- recommend alternative materials

- fix DFM issues early

- highlight high-risk features

- forecast bottlenecks

- tell you what will break

Is it like your internal engineer? Yes, that’s what a good manufacture partner can do.

What they do is not just a supplier, they act like an advisor.

That’s the value a good manufacture partner can bring.

Stats show:

- 70% of successful projects had early supplier involvement

- only 17% of failed projects had any early involvement

- 52% ignored manufacturability early

Your product is a demonstration of that it is only as strong as the weakest supplier in your chain.

How to avoid these failures?

We don’t talk about theories, but methods adopted by flying teams which get them through the difficult journey.

- Define timeline in cycles, not dates.

By cycle, you emphasize completion of the task, this is result-oriented, and outcome performance. This is just what plays critically in successful founder’s mindset on how they judge, think, and decide.

Instead, everyone will feel the weight of pressure from a deadline date. They’re afraid of being lagged, they worry about low performance, so choices are not optimal, actions are hasty, logical thinking chains are short, decisions are made out of short-term consideration…

Think in cycles:

- prototype cycle

- mechanical cycle

- electronics cycle

- certification cycle

e.g., instead of prototyping taking 3 weeks, assume 2 cycles.

2. Build financial buffers

Successful projects plan budgets this way:

- development × 2

- certification × 1.5

- supply chain setup × 1.5

- manufacturing ramp × 2

With such budgets, you’ll feel at ease when confronting surprises.

3. Building supply network in early years, not when designs are finished.

Talk to them even at concept stage, or years before you think you’ll be a founder in the future. Ask for warnings/suggestions, not just quotes.

Advice, don’t delete a manufacturer’s cold email directly, but read it and interact with those good ones.

4. Validate an MSM (Minimum Success Model) before scaling.

With current business operation, ask the difficult questions early:

- Do we truly make margin?

- Can we afford distribution?

- What is the return handling cost?

- What is the cost of customer acquisition?

If the business model fails, engineering cannot rescue it.

5. Fix core product vision

Whatever a feature seems attractive as it may be, freeze such idea.

“NO MORE FEATURES” should be a rule. Stop thinking of adding any new features to increase product attraction.

Vision drift within a cycle is harmful.

What to do with the vision?

Only for feedback from early stage test users.

6. Align engineering and procurement on the same page

One BOM. One version. One communication channel. They update with each other every check meeting. They synchronize immediately when a difference is found.

7. Remember: execution over idea

Ideas are cheap, free, no efforts to exert.

Execution is expensive, energy consuming, result-producing.

Execution is where most teams fall.

Conclusions: Respect the Reality

After attending and watching so many projects – from successes to failures, I truly believe success doesn’t reward the most creative, best-looking, most intelligent.

It rewards those who’re disciplined.

They’re disciplined at:

- timeline

- costing

- testing

- communication

- supply chain choices

- decisions

Every team has its shortcut, every shortcut will be paid for.

But you can still go to the finish line by avoiding as less as possible those failures or project killers.

As a manufacturing partner, your success shapes ours as well.

When your project is growing to be great, we grow with you.

And we hope to be the partner who stands beside you — from the first idea sketch, through the hard middle, all the way to a finished product in someone’s hands.

That’s only wish we have.